- +918533091875

- [email protected]

Our Services

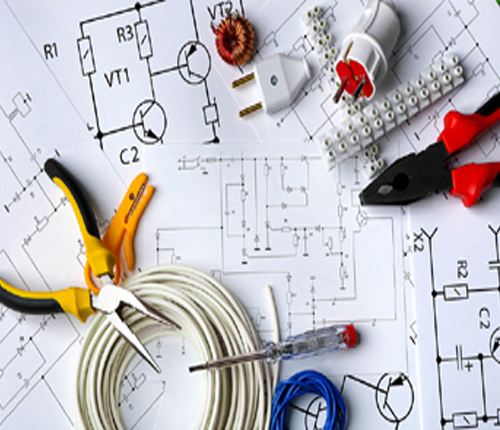

House Wiring

It’s important to understand some of the basic terms which are used when describing wiring. An electrical wire is a conductor, a material which conducts electricity. For household wiring, the material is either copper or aluminium (or copper-sheathed aluminium), although aluminum is not really used anymore. It can be stranded wire or solid metal conductor and in most cases, it is insulated, using a non conductive plastic coating.

Color coding is used both on the outer sheathing of bundled electrical cables and on the individual conduction wires within cables or inside the conduit. Understanding this color coding can help you identify what the wiring is used for and helps maintain consistency within an electrical system Cable coloring relates to the size of the wires inside the cable and the cable's amperage rating.For example, white-sheathed NM cable is used for 15-amp circuits, while yellow NM cable is rated for 20-amp circuits.

Total Maintenance

Make sure the outlets and the switches are working correctly. Check the ground wire to make sure the system is grounded properly. Look for the signs of rodents, insects, and water damage. Make sure the system is up-to-date with the safety codes and regulations. Keep records of electrical maintenance.It includes inspecting, testing, and repairing electrical equipment as necessary to prevent problems that could lead to a loss of power or an electrical fire.

In general, there are three types of electrical maintenance: Corrective Maintenance. Preventive Maintenance. Predictive Maintenance.Preventive maintenance is the act of performing regularly scheduled maintenance activities to help prevent unexpected failures in the future. Put simply, it's about fixing things before they break.Wire Maintenance Plan covers the cost of troubleshooting and repair of communication wires inside your home.

Commercial/Industrial

It is a systematic series of preventative measures to ensure the safety of all personnel working around the equipment, and the quality of the equipment itself. Electricity-related disruptions can set back business and production. That's why every outlet, appliance and machine should be well-inspected and maintained to ensure safe, reliable equipment. You might even be able to save aging equipment by repairing it before it breaks down.

Industrial Maintenance actions are essential to guarantee the safety of all those involved in the production process. With this practice, the good functioning of all industrial equipment is promoted.There are five notable types of industrial maintenance: preventive, corrective, predictive, condition-based, and predetermined.

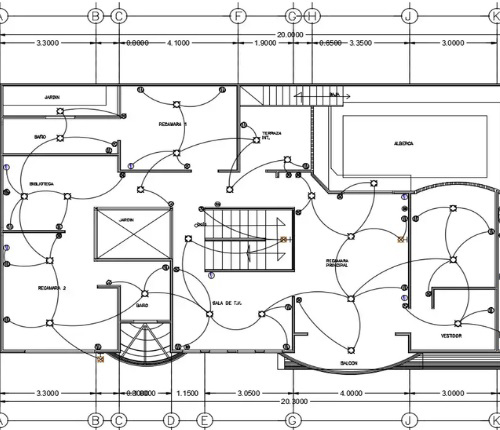

Electrical Drawing

In the current technological environment that is evolving at such a fast pace and where accuracy and safety are of utmost importance the services of electrical drawing are highly valued. Such services include drafting, drawings, analysis, and maintenance of complex drawings that show the electrical systems in various infrastructures.

Accurate electrical drawings are essential in industrial plants, commercial buildings, and residential complexes so as to ensure optimal performance, safety, and compliance with regulatory requirements. hese drawings are the maps for engineers, electricians, and technicians that lead them through the process of installation, maintenance, and troubleshooting. However, the advent of more sophisticated software tools has led to marked progress in the discipline of electrical drawing, allowing for more accurate and productive documentation of complicated systems.